Custom Wood Piggy Banks: Start to Finish

Let me show you how SandboxRanch.com makes custom wood piggy banks, start to finish at our shop!

There are quite a few steps involved, from purchasing rough sawed red oak lumber from the mill to making beautiful finished custom wood piggy banks, a variety of tooling is required from manual clamps with glue to power tools to multiple CNC platforms!

My goal with SandboxRanch.com was to make on-demand affordable wooden projects that were completely customizable, and that requires quite a bit of investment from tools to material suppliers to pull off correctly… it’s been over 6 months from seriously going ahead with this idea and actually getting things to the stage you see them now.

After the cutting of the rough sawed red oak and the glue-up, I end-up with a wonderful slab as you see above, only after all that previous work, can I start to do the router work required to transform this into custom wood piggy banks for customers across North America at SandboxRanch.com.

I’ve been designing banks for years, even before I even knew what CNC machines were, here’s a 3d animation of a design I came-up with about eons ago.

This CNC router is very special, so special in fact, that they no longer make it… what makes it so great? The gantry is super rigid because it doesn’t move, the table under the work is what moves, this means there aren’t any motors required to move the gantry, which means it can be super heavy and rigid, which all comes together to produce a fantastic finished result right off the machine.

The very first thing that our router does, after flattening both sides, is making the chamfering on all the edges of the banks that require it, I want to work my way into the bank, removing material as I delve deeper into it, this makes sure nothing moves on me as only vacuum suction is holding it down at the moment.

I generally run a test on one custom wood piggy bank before doing the rest, there are quite a lot of programming changes done after each production run as I hone my skills on producing the absolute best result possible for SandboxRanch.com customers, and this needs continual cycles of improvement and verification between each production run.

It’s incredible how much things have changed from the first concept of developing these custom wood piggy banks… it’s been quite a journey!

What the router is doing here is carving out all the insides of the custom wood piggy banks, the finish from this process is actually pretty good, but as with everything else, tweaking can improve things further.

The chip load is about perfect, the machine is very happy cutting through this very hard laminated red oak slab and it’s great to see, after all the work done previously, a finished product slowly emerging from all the sawdust and noise made throughout this process, making the final custom wood piggy banks.

Although making these custom wood piggy banks would be totally possible using just hand and power tools, I can’t imagine making thousands of these in that way, the repetition would be crazy and of course, any type of customization would greatly increase the time and costs involved with turning these banks into reality.

Now that the insides of all these custom wood piggy banks is almost done being roughed out, the next step along the chain is to switch bits (tool changers are awesome!) and using a finishing bit, going over every aspect of the bank to make things nice and clean, inside and out at SandboxRanch.com.

Here’s another banking concept I had years ago as well, this one could be easily adapted of course to the new processes developed with SandboxRanch.com‘s red oak piggy banks.

My shop may be small, but what it can produce is volume and quality is astounding – it’s the synergy between various CNC platforms that makes what would require a massive shop into what can be made using a little one.

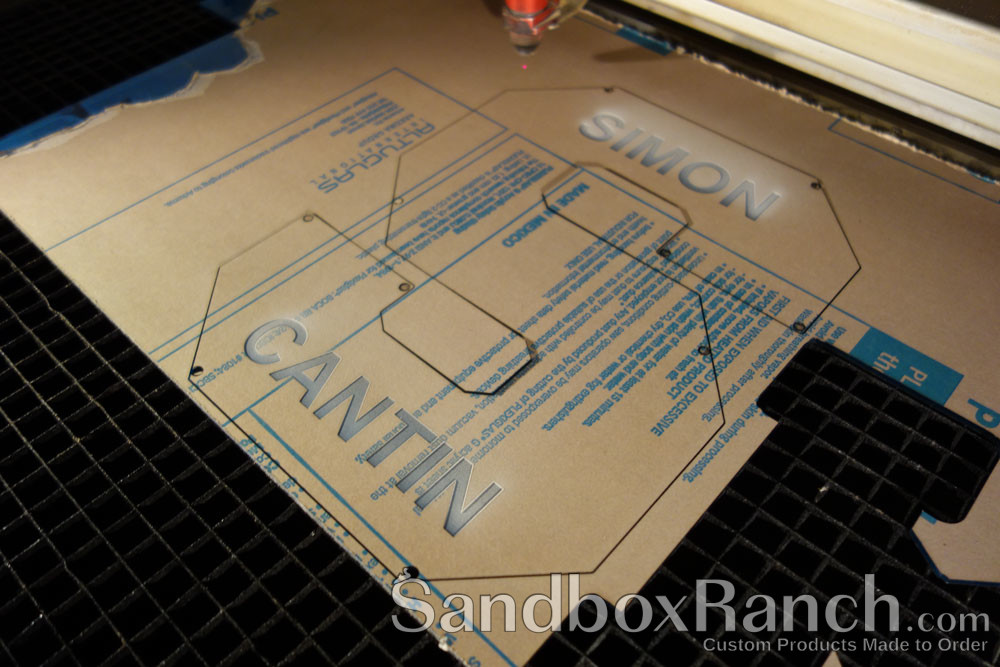

The finishing bit is now carving out the ledges all around the inner perimeter of the custom wood piggy banks, this is where the acrylic front will settle into, of course, that is CNC laser cut, so one CNC is helping another to complete one product.

In the above picture, you can see how the holes are drilled into the banks, the same process is also done on the matching acrylic or polycarbonate with the laser, which means that all I need to do is screw in the requested type for the customer of the custom wood piggy bank and it’s ready to ship after finishing!

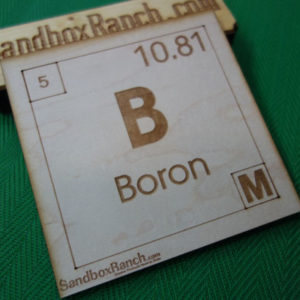

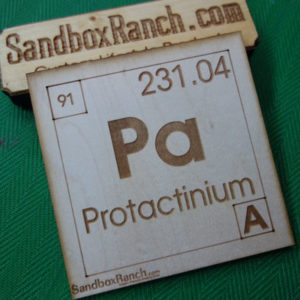

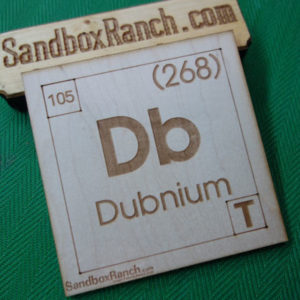

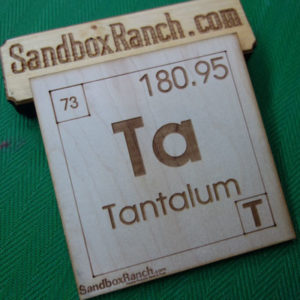

What I really enjoy about making these custom wood piggy banks is that each is very much unique, from the engraving to the finishing, there is an incredible diversity in what we can produce at SandboxRanch.com and offering them to customers however they want is great fun!

There is no other way to learn how to make quality custom wooden piggy banks than to do it, and it cost a lot of time and money to get to this point, I’m so happy I went through all of that to get to this point, it’s very rewarding to see where this began to where it’s going.

After all these steps are done, the final one is using the roughing bit yet again to carve out the perimeter of the custom wood piggy banks then using the finishing bit to do the same process but nicer, before all the banks can finally be cut out of the red oak at SandboxRanch.com.

I’d say that quite easily, half of the laminated wood that I spent so much time making ends-up being saw dust, the nice thing about hardwood saw dust is that it has some weight to it and thus, settles down pretty easily on the bed of the router rather than go airborne.

This production run of custom wood piggy banks is looking great, each time I make these, I get better results, faster, and with less problems that need solving!

Nesting these custom wood piggy banks is vital, I want to waste as little wood as possible and utilize as much of the laminated red oak as possible, so jigging things around for that perfect fit takes a bit of time but well worth it if I can produce just one more bank out of the slab.

Literally anything can be transformed into a custom bank, 2D objects to carved 3D all work great for this application, it’s just a question of time and getting things sorted so the possible volumes that could be coming in are possible to be produced in a timely manner.

The only part of this that isn’t fun at the moment is cutting them all out with the jigsaw, that’s a process that I will be refining further later in the year using a big bandsaw, that will solve one more pain point when making these custom wood piggy banks, again, slow but continual progress is essential to keep production going on these banks!

After the jigsaw did its work, it’s time for the routering out of all the ledges, this I don’t mind, I actually find it quite fun, but that can be improved upon like anything else, with experience and further investments in better equipment and processes at SandboxRanch.com.

Here’s what this latest batch of custom wood piggy banks looks like, just like this, without the finishing, they really look amazing… finishing just gives them a bit more pop while creating a barrier from the environment regarding humidity other issues present with natural wood.

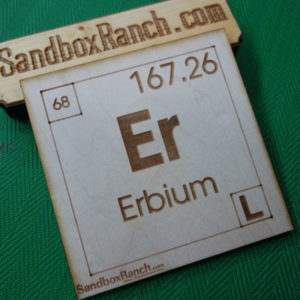

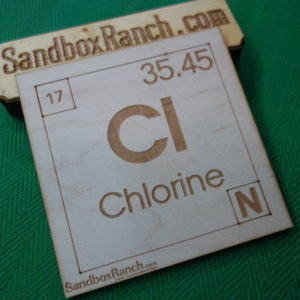

Of course, we aren’t limited to only the alphabet at SandboxRanch.com, custom trays and whatever else can be just as easily produced for you on demand and to order.

Like everything else in the shop, I make due with what works until I figure out a better system, right now, this process below for adding tung oil and letting things dry works fine, but as you can see, it doesn’t scale very well so I already have plans to make something far larger and flexible in the very near future regarding this aspect of custom wood piggy bank finishing.

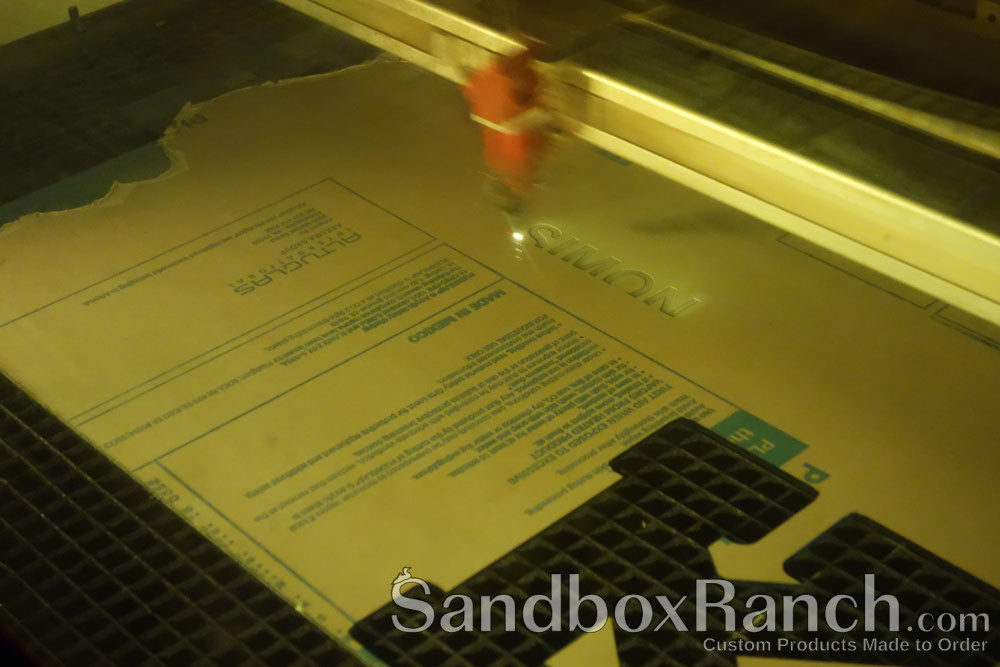

While the custom banks dry, the acrylic fronts can be cut out, yet again, a process that can be further optimized and refined but it’s certainly getting there at SandboxRanch.com.

Simon, my son, gets an extra special 12″ tall custom wood piggy bank, using blue transparent acrylic with his name engraved on the front, he doesn’t know his name yet but this is a good reminder!

I’m very proud of how this batch came-out, you can see the diversity of paint fills, names and alphabet possibilities that SandboxRanch.com offers you… and a lot more is coming in the pipeline!

Want something custom? Visit SandboxRanch.com right now!