Custom Hardwood Banks: Simon’s Christmas Bank

Making custom hardwood banks continues at SandboxRanch.com but today we’ll focus on finishing-up my son Simon’s Christmas Bank which is made-up of two layers, the front is a tyrannosaurus rex and the back is a raging volcano.

As with all the banks that we made at SandboxRanch.com, they begin with rough sawed lumber from the mill, in this case, we are using Poplar, a wood species I’ve grown very fond of as it paints and stains way better than Oak and is easier to work with.

The first step after bringing in a few hundred pounds of rough sawed kiln dried lumber into the shop is to begin processing it into smaller, more manageable pieces so that it can be more easily transformed into high quality custom hardwood banks.

There is quite a bit of woodwork involved with getting the slabs ready to transform into custom hardwood banks, several steps of cutting and planning, before I can finally make items of joy for people across North America.

This isn’t my first volcano bank that I plan on making, I designed this one YEARS ago, a different process certainly, but the result is the same, a fantastically unique bank!

My shop isn’t the biggest but it’s efficient and has all the tools I need to more than keep-up with production schedules of not only SandboxRanch.com but also the custom fabrication projects over at my main business CNCROi.com.

Once I have rough sawed Poplar lumber cut into sticks, it’s time to go ahead and glue it all back together into slabs, beforehand, I need to flatten and clean-up the two opposing sides to make sure I have a perfect seam so there aren’t any voids.

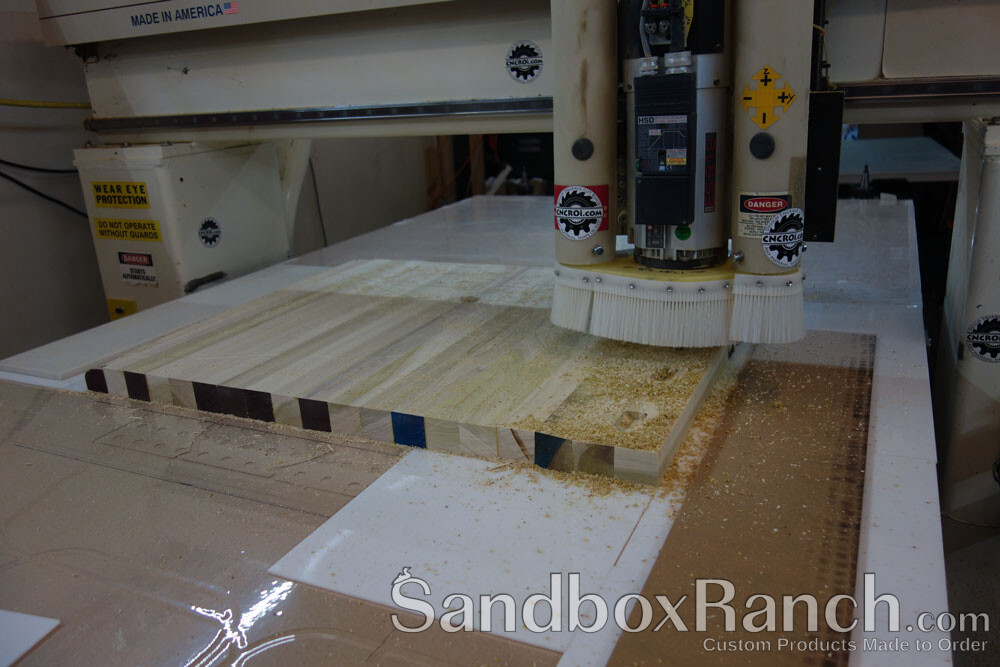

I bought a 6″ jointer to do the work you see my Thermwood CNC router doing here, flattening and cleaning two sides of the wood sticks, but after using it a bit, I decided the CNC is the best way forward, it’s faster, produces a better result and far less physically taxing on me.

After two opposing sides of the Poplar sticks that will be transformed into custom hardwood banks shortly are flat, clean and parallel, the next step is gluing them together – everything up to this point has been prep, not production at SandboxRanch.com.

I’m always amazed at just how fantastically tight the seams are with the slabs of hardwood that I make at my shop, I guess it a testimony to having every side of these sticks cleaned-up multiple times.

This video shows you how the T-Rex was made, many of the steps you see in that video are similar to what you see in this blog post but there are small refinements that if you pay attention, will show you a gentle further evolution of production efficiencies.

Once the glue is dry and fully cured, I can then stick the laminated slab of (in this case) Poplar onto my CNC router bed and flatten and make parallel the front and the back, this is where I end-up with an incredibly clean slate to begin making custom hardwood banks for SandboxRanch.com with.

You can compare the slab just a few pictures up and the one below, it’s the same slab, but wow does it look clean and then I can begin production almost immediately, the nice thing about this approach is that time and machine is used, not too much of my physical body, which saves a lot of time and make the custom hardwood banks cost-effective yet still totally made to order.

It’s great to be able to not only control but be able to optimize each and every aspect of the production of custom hardwood banks, from wood to pixels, it just gives me so much creative freedom to innovate for SandboxRanch.com customers.

As you can see from the picture below, I could easily mass produce A LOT MORE BANKS in one shot, and even set-up a multi-step process where one part of my 5ft x 10ft table could flatten the sticks and make them parallel (a fast process) as I make custom banks, across several batches on laminated slabs, at the other end.

Each and every aspect of these banks has been optimized, and each time I make these, I further improve on the design and processes involved with making these custom hardwood banks for SandboxRanch.com – so things are just getting better between each production run.

I designed a whole series of laser cut banks, which will soon be coming to SandboxRanch.com, it’s just an alternative method to produce something that has a different aesthetic to it.

Having a super-rigid machine and wickedly overpowered spindle and associated CNC router means that what I produce is almost ship-ready, using Poplar hardwood does produce a few little fuzzies here and there that are quickly sanded but otherwise, what comes off the table is basically ready to ship right away to SandboxRanch.com custom hardwood banks customers.

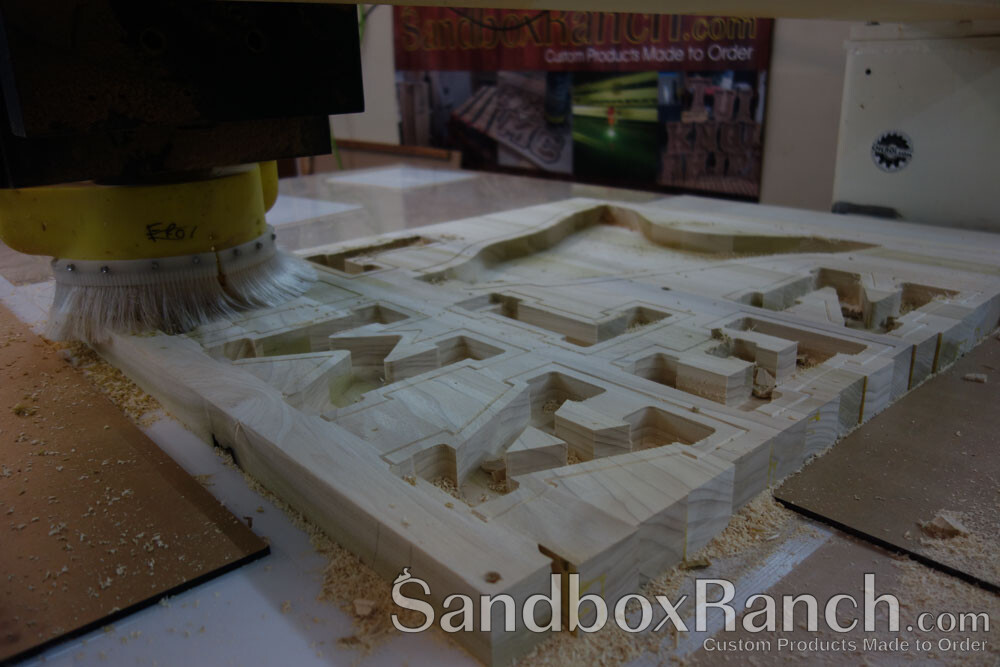

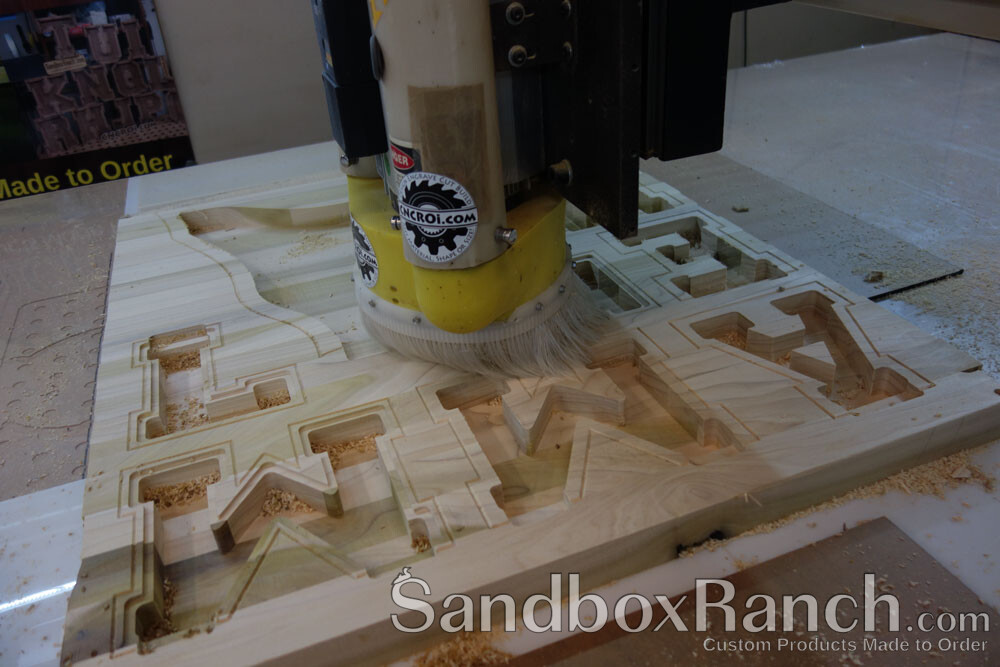

Making these custom hardwood banks is a multi-step process, each time I carve out one detail, it’s followed by another one and so on, until the entire bank is almost cut-out and ready to be refined with my table router.

The longer this laminated slab of Poplar stays big and together, the less likely I am to have production problems for these SandboxRanch.com products, the slab is of course screwed town as well as being vacuumed down to make sure nothing moves from start to finish.

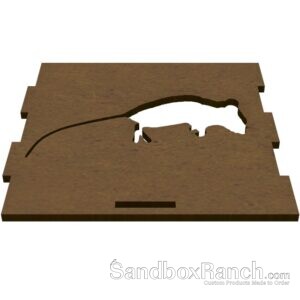

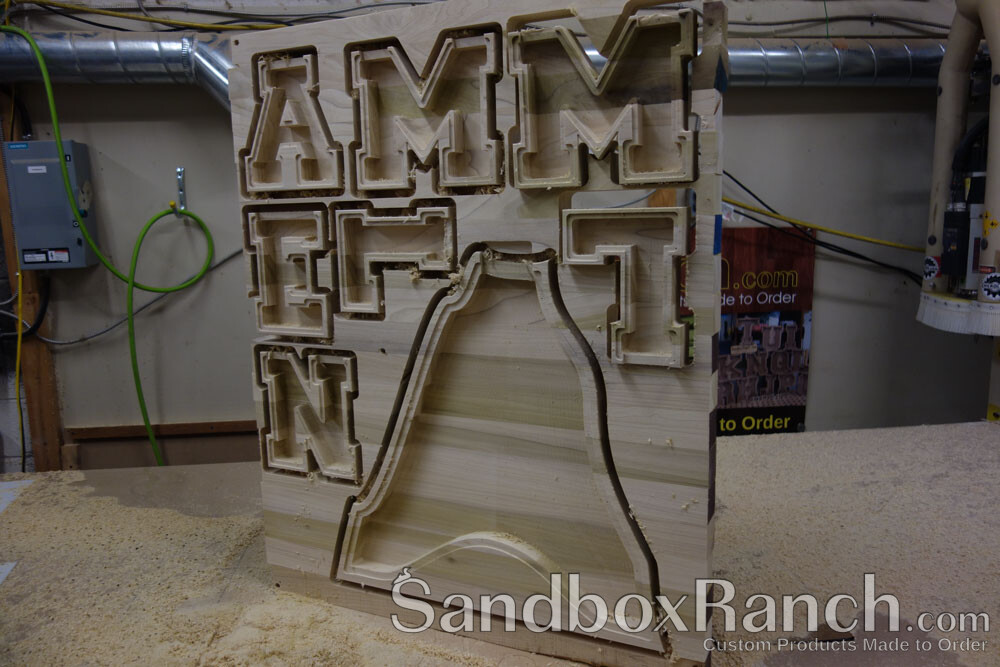

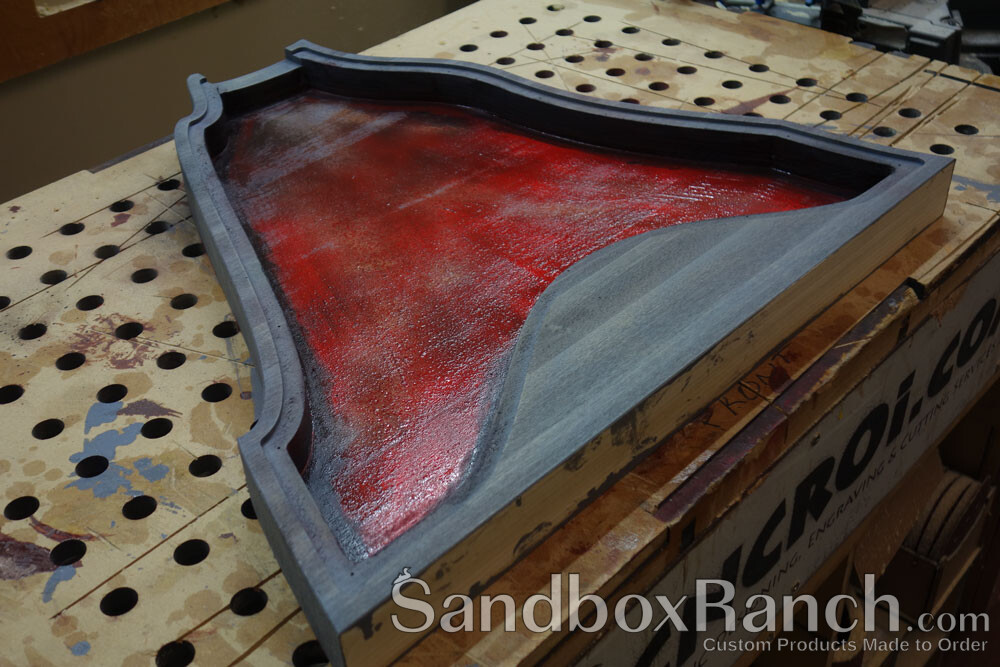

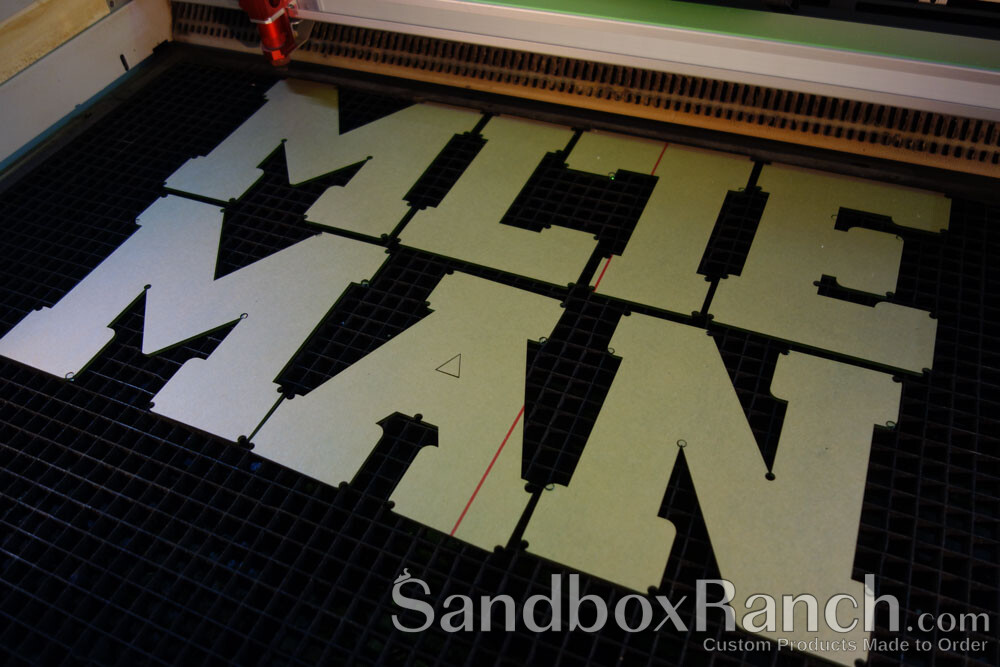

You can now finally see the massive volcano bank that I made that will go in the background of Simon’s bank, this custom hardwood bank is 22″ tall for reference, the other letters you see on this slab are a few other orders I had to get done at SandboxRanch.com using square letter bank shapes.

Want to see how far things have changed making these custom banks in early 2022 to end of 2023? Watch this video right after watching the one I produced at the top of this blog post.

A bit of clean-up and you can see how fantastic these custom hardwood banks look, they have their screw holes already done and best of all, these will totally match what I make with my CNC laser for the front acrylic window so that process of unification is so much easier than how I did things in the first run earlier in the year.

After these custom hardwood banks are cut out using my table router, only a little spot sanding is required as some areas of the Poplar are harder than others, more fuzzy than others and as a result, need a little fine tuning before shipping.

I decided it was time to make a rough test to see how Simon’s bank would look like once fully assembled, the Tyrannosaurus Rex was made earlier and as it’s so tall with not much depth, it needed a back support, which is the main purpose of the volcano custom hardwood bank.

Poplar stains wonderfully, that’s what the grey is, and the inside of the volcano bank is painted, again, poplar works great for this as well, Oak would have taken a lot more steps to get to the same ending and cost more as well.

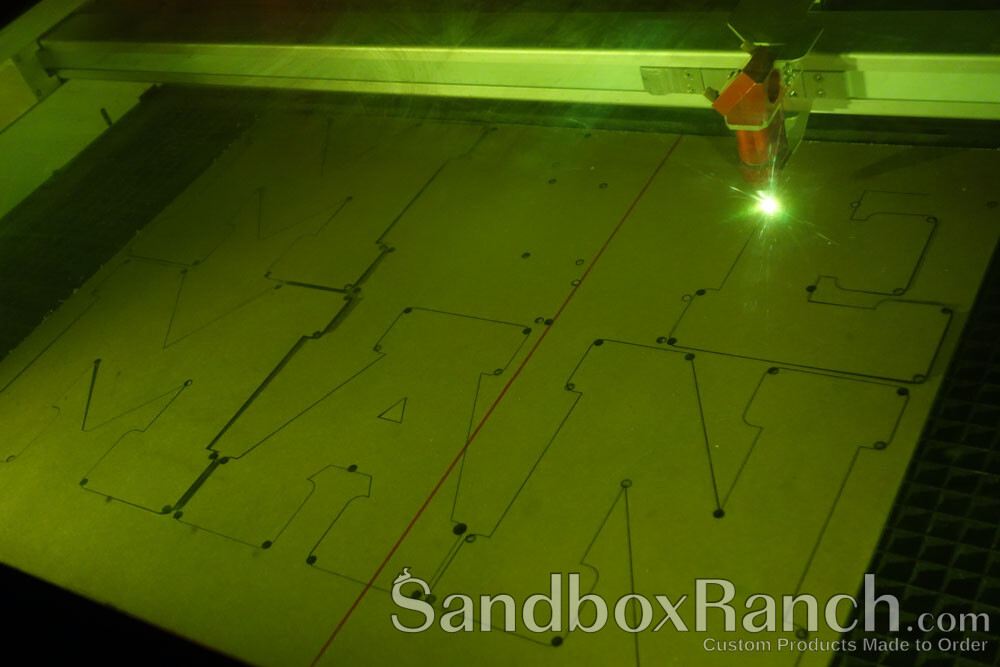

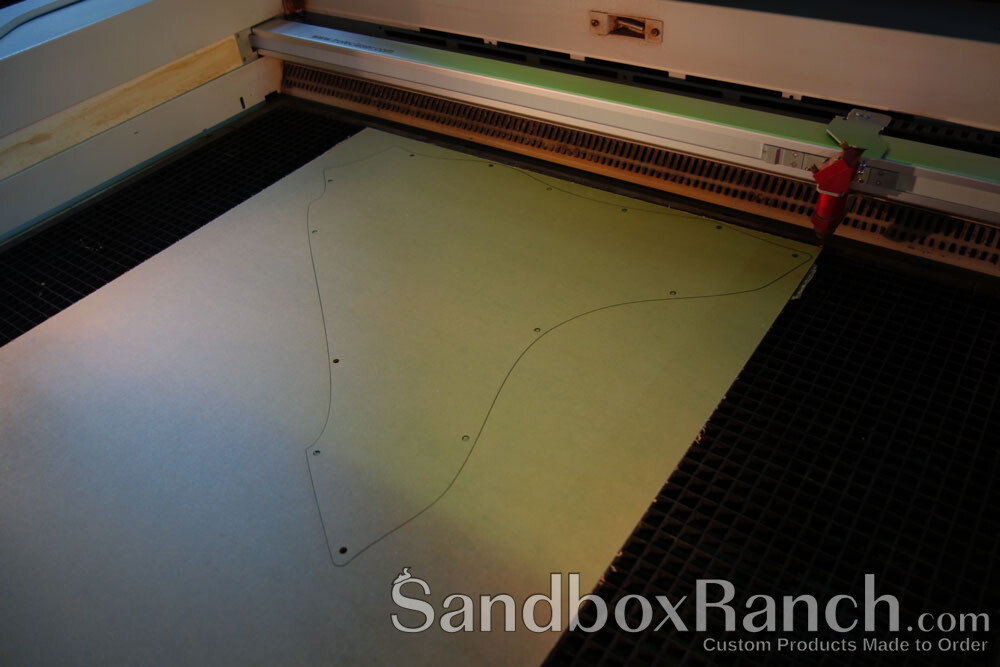

This batch of custom hardwood banks all had light green front acrylic windows so I cut them all in one shot for SandboxRanch.com, I think the light greed looks fantastic with natural Poplar, the contrast is just enough to accentuate the wood.

I’m definitely no stranger to doing work with my laser, it’s one of the most used machines in my shop, and it’s amazing just how versatile it is, here’s a plaque I made just the other day, where instead of making a bank, I made a recognition plaque.

The acrylic has masking on both sides to protect the window during the transportation of the sheet, as such, it must be removed to reveal the acrylic after it has been laser cut, laser cutting produces smoke and can burn the acrylic as well where it isn’t intended to happen, so the masking protects against that as well.

Letters, volcanoes, it makes no difference, the laser cuts it all out no problem, above was light green and below as clear acrylic, both 1/8″ thick for the SandboxRanch.com custom hardwood banks.

Here’s a close-up of Simon’s bank after I finished the assembly of all the components, this doesn’t photograph very well in the shop so a close-up was the best way to show the painted part inside the volcano and the mirror finish on the inside of the dinosaur.

And the finished bank assembly, two banks, should hold Simon over for 2023 as he filled-up his 12″ tall S bank within a month of receiving it.

Looking for custom hardwood banks? You’ve found SandboxRanch.com!