Thermwood Beast Activated!

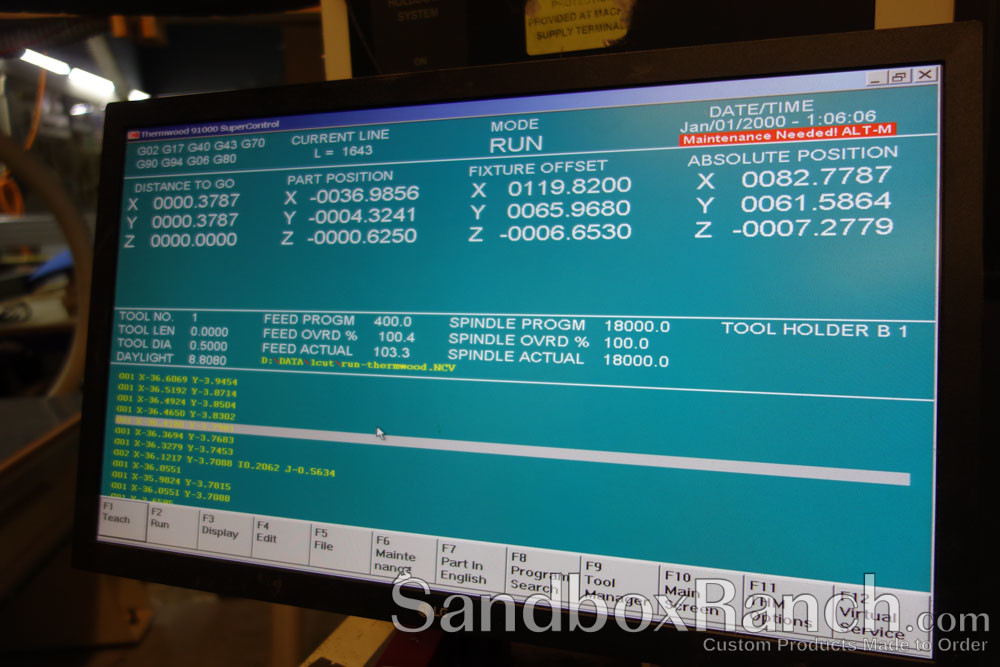

Thermwood has replaced our ShopBot PRSAlpha for production at SandboxRanch.com and the change in production quality and speed has been phenomenal!

That being said, this blog post is a bit of a transition as over the past 3 months, I’ve been slowly moving things to the Thermwood beast and using my Shopbot less and less throughout this time, hence not posting much on this website until the entire production was finally moved over, so some of these photos and videos are showing how things “were” done, not being done currently, at SandboxRanch.com.

Most of the limitations I had at SandboxRanch.com since inception has been my Shopbot, there is nothing wrong with this machine, it has served me incredibly well through the years, but for the speed and quality of production I was gunning for regarding these custom red oak banks specifically, I was just beyond the limit of what was possible with it.

Some jobs, such as flattening, the Shopbot is just as good as the Thermwood, this is a relatively simple task that doesn’t require much horsepower or rigidity in the overall machine, and I’ve done a ton of this type of work at my main business CNCROi.com through the years with phenomenal results.

Just to give you an idea of the evolution that SandboxRanch.com has experienced over the past three months, check-out the first video of me making custom banks to the video I’ve uploaded for this blog post.

The issues I was having with the ShopBot was that, by its very nature, it isn’t a rigid machine, or a heavy one at that, for 95% of the jobs I do at CNCROi.com, this poses absolutely no problem, but when it comes to making custom red oak banks, this became a glaring issue that I could only compensate so much for until I decided to “give-up” and look for my dream machine, the Thermwood.

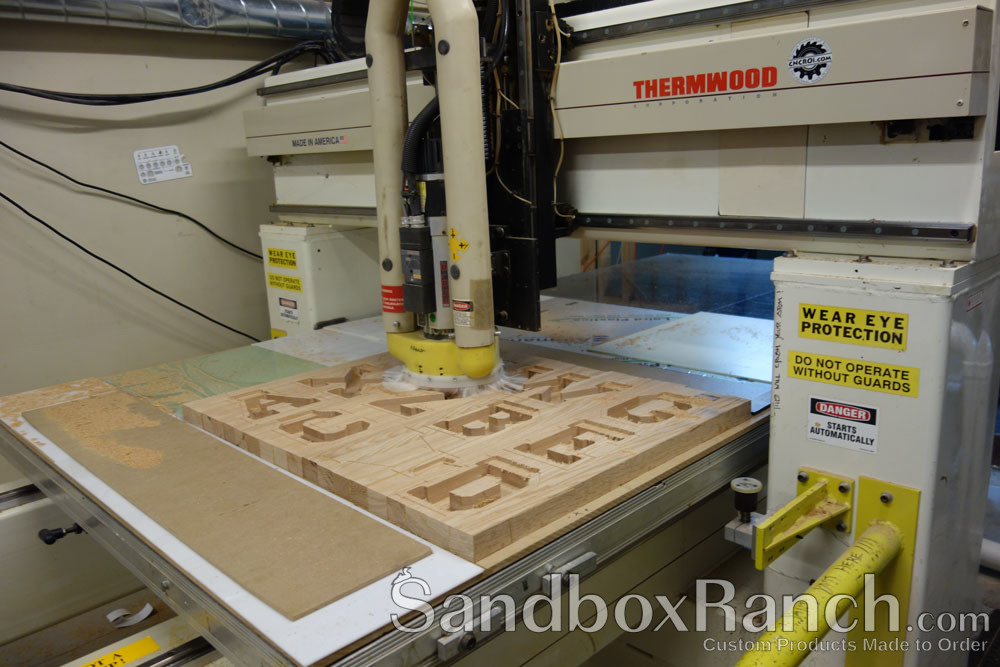

The Thermwood now residing at SandboxRanch.com has rigid frame and solid gantry, which means no design or weight compromises were required in order to create a moving gantry, instead, the table moves back and forth, which in itself seems like the same difference, but the table is super rigid and heavy on its own on a solid steel frame, so it can absorb vibrations endlessly without issue, as does the static gantry.

The other major improvement going from the ShopBot to the Thermwood was a tool changer, I plan on adding more tooling so I can have even more down the line, but not having to manually change tools any longer is a MASSIVE improvement on its own in speed and end-quality of these custom wooden banks throughout the production cycle.

With my Shopbot, having to change tools manually means you want to use and change tools as little as possible, so I limited myself to two tools, with my Thermwood, I use all four during production and can further optimize the selection, so instead of one tool change during production on the Shopbot, I now change tools 6 times between the four tools I use.

Another MASSIVE improvement has been the vacuum table, you’ll notice I don’t use screws or other wood pieces to hold down the “once flattened” red oak laminated board that these custom banks are cut from, the suction power of two massive vacuum pumps holds things perfectly in place.

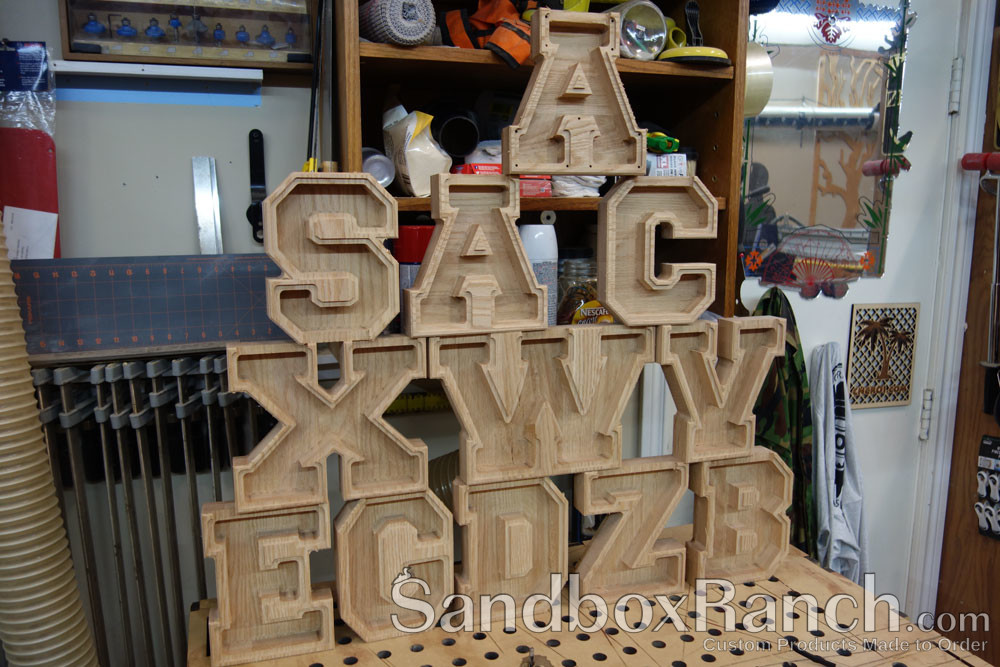

This is the first preproduction of the banks I did, some were good, some were not, regardless, lots of work getting them ready for customers.

I only had to create a sled to hold the glue-up down for one side as it doesn’t lay flat enough to create enough suction to hold everything in place, a very minor inconvenience compared to the process of screwing and unscrewing boards around the red oak lamination.

In these photos and video, I’m still very green to the capabilities that Thermwood offers me now with SandboxRanch.com, there are already programming updates I’ve done for the next round of custom wooden banks and tooling to further streamline production, but at least now, I’m able to focus on speeding things up rather than down, as I had to do with my ShopBot PRSAlpha.

The Thermwood is about 12 000 pounds, so it’s significantly heavier than my Shopbot, so any vibration is greatly dampened and wow do you see those results in the end-product for SandboxRanch.com.

The spindle and related bit cut through red oak as if it was butter, the results are ship-ready right off the machine with only a little sanding here and there (this is real wood) before the finishing must be done.

So this has been the journey I’ve been on over the past 3 months and although it has been very expensive in time and treasure, I couldn’t ever see myself going back to the old ways of making SandboxRanch.com products, I don’t know how I achieve the very good results I did previously, but having a full-on industrial machine is night and day.

My last run, you saw many improvements throughout, and they are very much continuous for each run that I do, there is always a few tweeks that can be made to make production faster, better and at a higher quality overall for SandboxRanch.com products.

Going from my Shopbot to Thermwood also required me to upgrade the tooling, and during the testing through calibration phase, I wore out much of it, so these images look rougher than they really are now for SandboxRanch.com products.

You can see in the above photo through, just how clean and sharp all the custom wooden banks look straight off the machine, I spend so much time optimizing and sanding the results from the ShopBot, that looking at this, and how effortless the Thermwood made it to this point, this is really a thing of absolute beauty!

After the Thermwood finished cutting out this batch of custom banks, the next step was using a jigsaw to cut them out of the laminated wood followed by using my router table to cut the thin skin all the banks have, which holes them in place with the vacuum table, as a final step before finishing and final inspection.

After the CNC routering is done at SandboxRanch.com, the next step is to make their matching acrylic (in this case) front windows, you will notice in the above photo that the top “A” has holes all around, yep, I used the Thermwood to test-out pre-drilling all the holes in these custom wooden banks as well… with fabulous results!

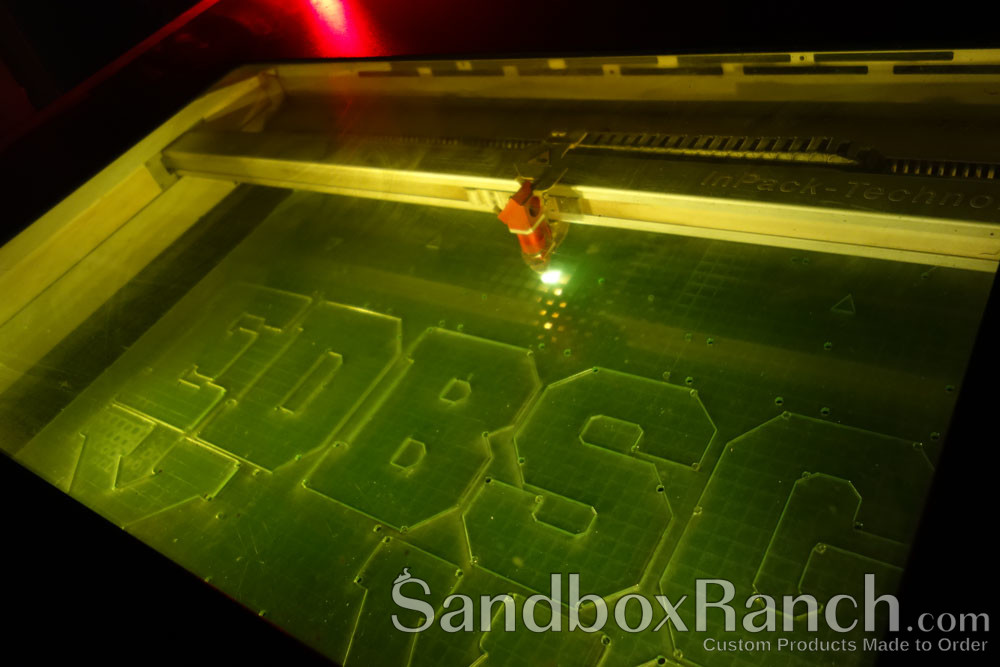

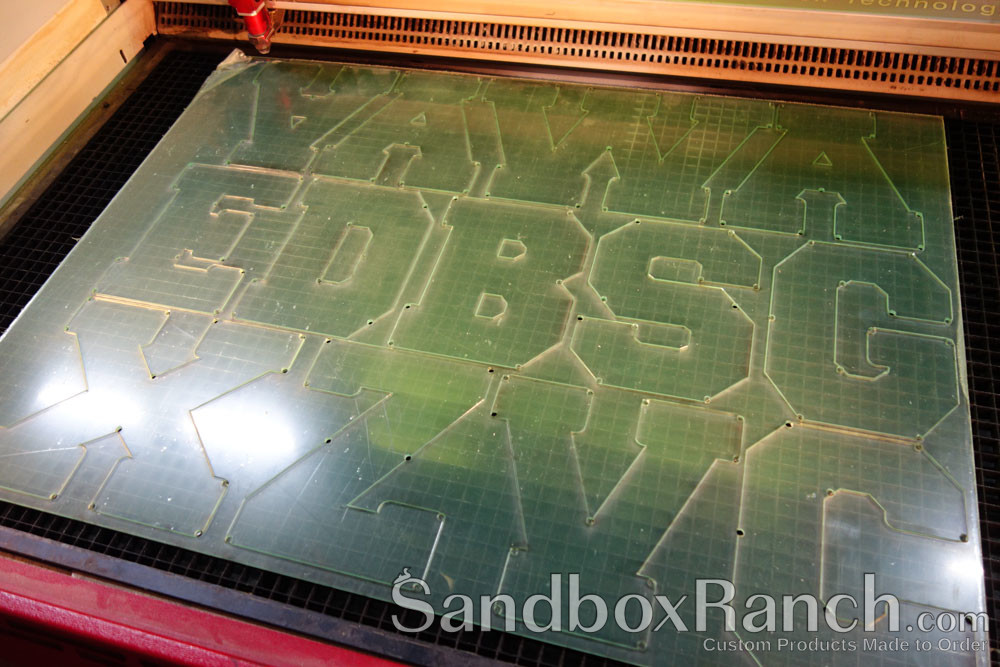

Laser cutting out the acrylic has been the same since inception of SandboxRanch.com, I have an amazing machine for that process so there is no need for any upgrade or improvement at that end.

All the front windows are now cut, they are transparent, the green you see is the masking on both sides to keep it “clean” until the very last step of marrying the red oak to the acrylic using screws.

Here’s what the final results look like, absolutely astounding… BTW, this is absolutely not a rub against my ShopBot PRSAlpha, if it wasn’t for that machine in my shop through the years, my Thermwood wouldn’t exist, it’s an incredible machine that has served me incredibly well through the years and will continue to do so for its next owner.

Want custom wooden banks? Buy them online at SandboxRanch.com.