Custom V2 Square Hardwood Banks All Updated!

This is the third or 3 posts outlining the new updated V2 square hardwood banks on SandboxRanch.com, the site is now updated and we’ve transitioned all new orders to the new design.

Here’s the videos showing the first two so you can gain an understanding of the process we’ve been through bringing these newest designs to market and why.

Of course, before doing a refreshed design of our square hardwood banks, I did the same with our rounded banks which were in far higher dyer needs.

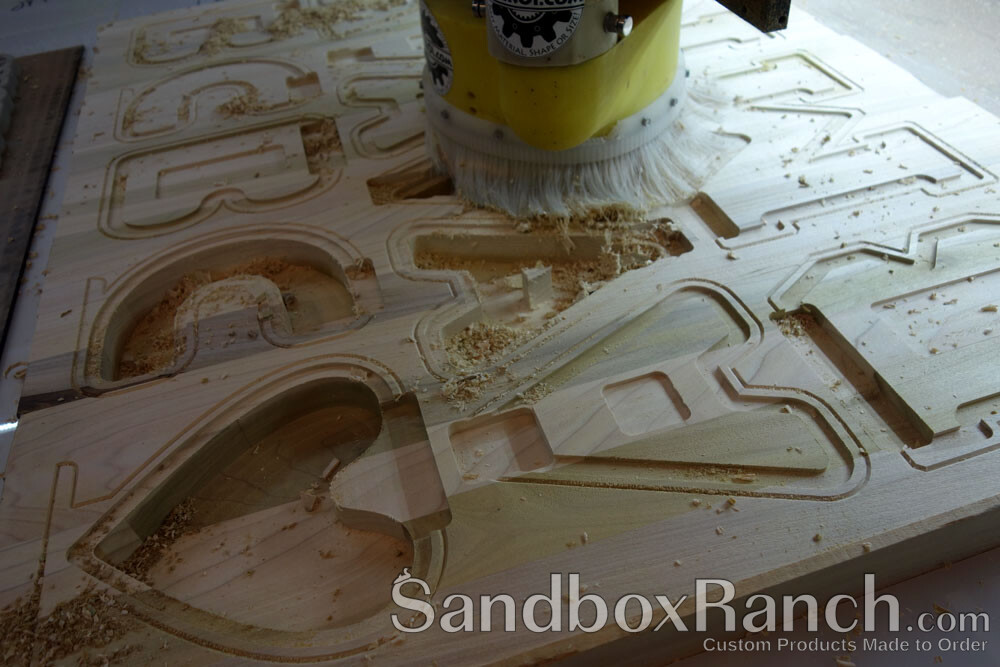

For this production round, other than the banks, I decided to magnificently upgrade our Thermwood CNC router beast to have LED lights under the gantry as I was so tired of having poor lighting where most of the work was happening in the shop.

The jigs I made at the very start of this journey towards making custom hardwood banks for SandboxRanch.com customers, square or otherwise, are now starting to show their age and I have enough experience with them now to start revising them to be more functional for their intended purposes.

Even simple tasks like just joining sticks of wood together and gluing is quite an art form to get right, too much pressure, it bows (thus requiring more flattening and making the overall slab thinner) and not enough, they fall apart or have spaces in them.

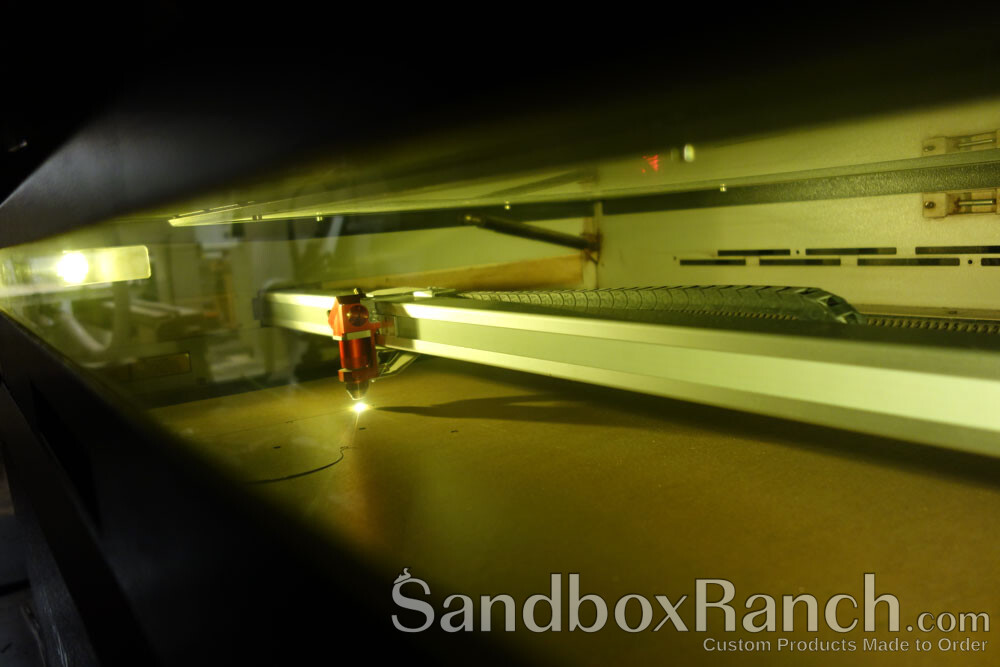

See that light under the gantry, it really plays a number on the camera and video but wow, I don’t know how I lived without it for the past year, it’s so nice to be able to see brilliantly, I used two T8 LED strips, during production to see how well the carving is taking place for these custom square hardwood banks for SandboxRanch.com.

This is quite a change from the very first run of custom hardwood banks I made for SandboxRanch.com.

You see the shininess on the seams of the poplar hardwood slab I laminated in the shop? That’s glue, and that all needs to be taken off, as you see in the related picture below, in order to have a nice clean and smooth piece of wood before SandboxRanch.com actually transforms this into solid square hardwood banks.

Once both sides of the slab are cleaned-up, the next step is making the banks, just about all of the banks we make at SandboxRanch.com have a chamfer, it’s a simple upgrade that really adds a lot aesthetically to the physical hardwood banks.

Custom hardwood banks made by SandboxRanch.com can be made into any shape or size, here’s what I made for my son Simon.

With the light shinning over the work being made, you can actually see far better any deviations in height, and the clarity on the wood itself really shines a lot, now I can see things without having to squint or with any doubts.

Each time I do a production run of these custom hardwood banks with my CNC router, it’s better than my previous run, incremental improvements might be small but over time, they build-up even if I’m the only one that notices and not necessarily SandboxRanch.com customers.

To me, a custom hardwood bank, which I call generational banks, represent a harmonious fusion of artistry and functionality, SandboxRanch.com is thus offering you a unique opportunity to own a meticulously crafted, personalized, and environmentally sustainable object.

Whether it’s for personal use or as a thoughtful gift, a custom hardwood bank becomes a testament to the enduring allure of crafted excellence in an increasingly mass-produced world, each one of SandboxRanch.com‘s hardwood banks is unique in its own special way.

Couple’s banks are always a popular choice, two banks made “together”.

The major difference between Poplar and Oak, which are the most popular options on SandboxRanch.com really comes down to the aesthetic you are after, if you plan on painting or staining your bank, or have us do it, then Poplar is the best choice forward but if you want something with very strong grain patterns and a bit more weight to it, Oak is the winner.

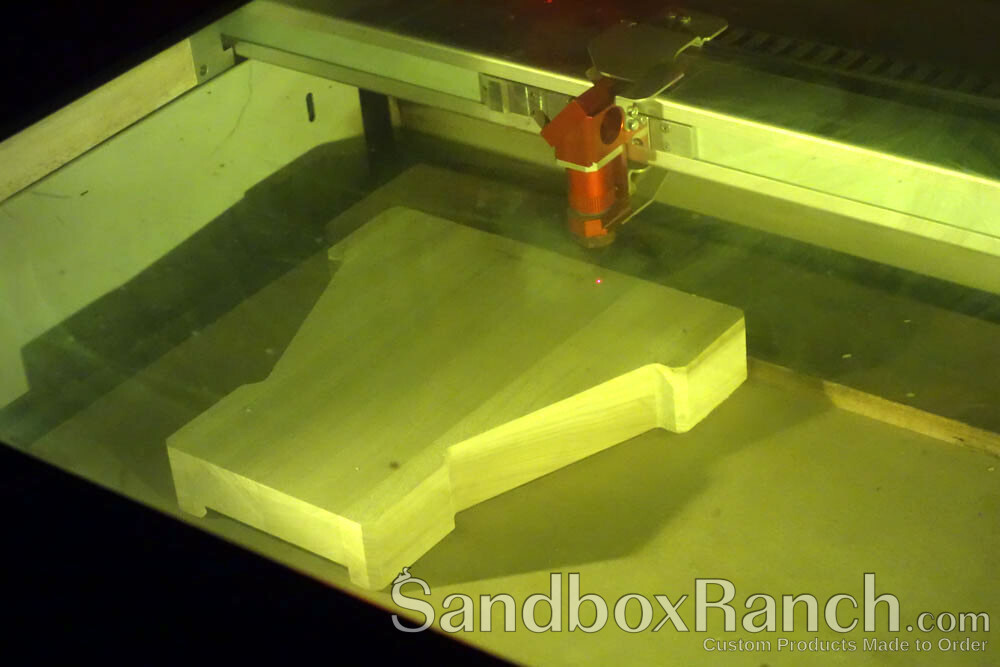

Once most of the carving is finished, you can see how the banks will mostly look like and this is also where I can see any issues such as problem knots etc. but in this case, everything looks great!

Now for the coolest part, drilling the holes, it’s a very small thing for a machine this big and powerful but doing this on the CNC machine was really a game changer for SandboxRanch.com, no more templates to manually drill holes, just get the machine to do it precisely each and every time!

SandboxRanch.com can produce custom hardwood banks using any wood species you want, if you want something truly unique, contact us ahead of time and we can make these out of Mahogany as easily as Zebrawood!

The drilling operation is generally when I change the dust extraction skirt, as the final cutting out of the custom hardwood poplar banks is almost all the way through the laminated slab so I need a less-high one to get the dust extraction to work properly.

There are two steps towards fully cutting out these square hardwood banks, the first is the roughing bit, this removes most of the material and then the second finishing bit cleans-up and smooths out all the edges so very little sanding is required afterwards at SandboxRanch.com.

Right off the machine, these square hardwood banks are just about ready to ship, they need a little laser work before being packed-up and ready to go to their new homes.

Although these videos might seem to get a little repetitive, they really aren’t, every aspects of production is improved in between each production run for SandboxRanch.com products.

After the CNC routing is done, it’s time to route these again using a power tool, this process goes even faster as I’m just removing a very very thin skin left over from the CNC on these custom square hardwood banks.

Before the routing can be done though, I find it better to just cut-out all the scrap around the banks using my bandsaw, this way, the routing is just along the edge and nothing else is left, though in my next run, when the banks are at the point you see below, I can just router them directly as the process is faster than using the bandsaw to remove this for SandboxRanch.com customers.

You can clearly see the little skin left from the CNC router in the image below and the spinning router in the middle of the table that will re moving this from the soon to be generational banks.

This is s two-pronged approach, while the router is doing it’s magic, the laser is doing its, I don’t have both running at the same time typically though I easily could, just because I want to document the entire process and I only have one camera to do it with but both machines, and then some, could easily be running at the same time.

Any shape, size, wood species or anything you really want… REALLY!

The back of the banks can also be laser engraved with the SandboxRanch.com logo once the acrylic is done and this is where a message could also be added to the back, technically, I could be busy routing out the shapes while the laser does it’s work and the router making more banks to cut production time by 2/3rds but at this point, I don’t have that much of a time crunch to contend with and have the machines doing other work for CNCROi.com in the meantime.

Once this run of banks is all assembled and ready to go, this is typically where I’d start packing, but for this run, the 3rd of 3, I kept all the custom square hardwood banks I made to this point to take a group photo.

Here’s the mix of banks I made in this run of both square, many extra rounded letters and the special heart bank for SandboxRanch.com…

And here’s the group photo of all the V2 custom square hardwood banks, just love the updated design and how they all come so well together!

SandboxRanch.com is now exclusively producing V2 of these custom square hardwood banks, the old ones, the file are kept, but consider this a relaunch of our most popular style of banks.

Need custom banks? Order online or contact SandboxRanch.com right now!