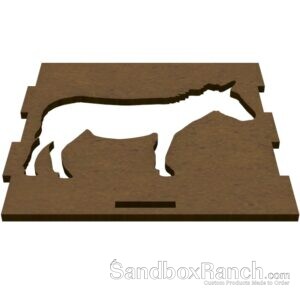

Red Oak Custom Animal Paw Trays

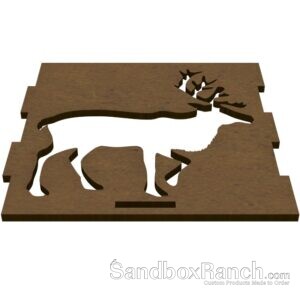

SandboxRanch.com is now launch one of a series of custom red oak animal paw trays design, just some amazingly unique items that are customizable to your desire and are great for everything from holding keys to candy.

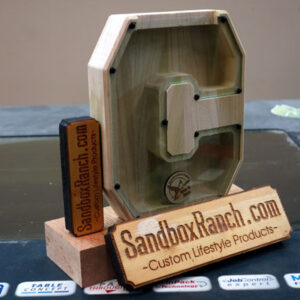

As with our custom letter banks, these custom animal paw trays are made from rough sawed red oak lumber, which we then cut to size, laminate, flatten and then go right into production.

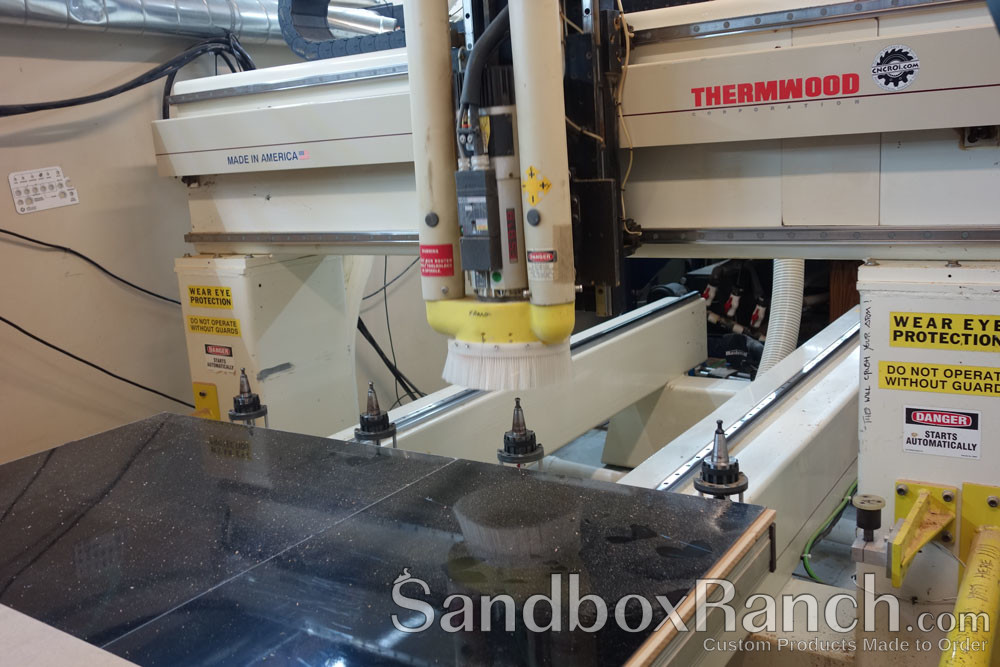

Now that I have my super rigid CNC router up and running, I can make things that would otherwise have been a lot of trouble, and effortlessly switch bits to make a higher quality end-product for customers far and wide looking for unique gifts and personalized items from SandboxRanch.com.

Rough sawed lumber is first cut in half and then transformed into strips that are then further flattened, laminated and then flattened again before being transformed into finished (in this case) custom animal paw trays.

As the steps involved for this project are the same as the banks, and that’s on purpose, it means we can mass-customize and personalize a host of different products at the same time, these cost efficiencies directly benefit you, our customer, because we aren’t stuck making separate production runs between different items as the general wood species and thicknesses are shared between items.

I like documenting my work, it shows me how much things have advanced through the months and years, production runs get bigger, efficiencies get more so and the fun just keeps on growing throughout!

I’ve grown to rather enjoy the overall process of producing laminated boards at SandboxRanch.com, it’s actually quite fun transforming wood that most people wouldn’t give a second look to into items that are not just beautiful but highly functional in a variety of settings and applications.

The marks you see on the red oak strips is actually caused by my little table saw, which I plan to upgrade shortly, it’s like my Shopbot that you see working right now, fantastic for 95% of what we do at the shop, but that 5% is the area which I’m focused on improving over the next year or two as I move my equipment from very good to full-on industrial quality.

After the flatting process, you can see how beautiful the red oak looks, after glue-up and compression, the transformation is complete.

You can see how the steps are very similar to the last production run of custom red oak banks for SandboxRanch.com.

I flatten three sides of the red oak laminated boards, this products the best results for the glue-up consistency wise, of course, after glue, all of this needs to be flattened yet again on both sides, so I’m am chewing through a lot of wood at SandboxRanch.com to produce these laminated slabs of red oak, but the results are well worth it.

For this production run, I was making many laminated boards, as such, it’s was a rinse and repeat to produce these, as I’m still transitioning from my old CNC router to the new one, that’s why you see both in the video and photos, but soon it will all be Thermwood.

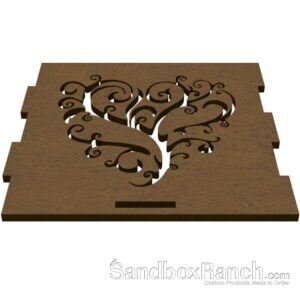

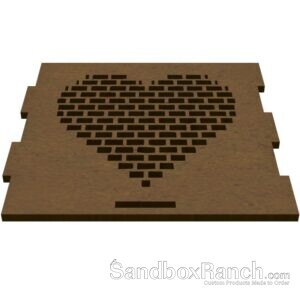

For these little animal paw tray, my goal, like the banks, was to offer a unique product that was cost-effective, can be endlessly customizable, and is both useful and aesthetically pleasing.

It might seem like there is a lot of work in the physical world to make these animal paw trays, but there is even more in the design aspect, to make sure I can make something for customers that doesn’t cost a fortune and where I can gain efficiencies of scale for SandboxRanch.com products.

States always make for great trays, yet again, a whole line of these are coming soon… it’s amazing what we can produce at SandboxRanch.com.

This was glue-up number two of many more to come, I lost count of how many I did in this run but I find doing the first half of all these jobs, making the custom laminated slab, works best doing the one after the other rather than just when I need to make custom banks and trays for SandboxRanch.com.

The glue needs a minimum of 24 hours to dry but I generally give it a lot more than that, there is no harm in having these glued-up longer than necessary before carving them out at SandboxRanch.com to become custom products but there is harm if I didn’t allow for proper bonding of the laminated strips.

Here’s the third board of laminated red oak that I glued-up, you can see the top looks rough, this doesn’t matter as the bottom and two sides of these pickets are what matters, this will be flattened yet again by the router and as a result, made parallel and cleaned-up in one step.

Now for the second stage of production for these red oak custom animal paw trays, actually cutting them out at SandboxRanch.com.

Shooter trays are another item that will be coming to SandboxRanch.com soon, but don’t let you not seeing it available yet on the site dissuade you from contacting us with your design and allowing us the opportunity to make it before they are officially online.

After flattening the board, removing the dried glue and the rough surface on the top as you saw earlier, the trays are cut in quick succession, as I’m new to many aspects of this using the Thermwood, I forgot to orientate the board properly so I was cutting is wide rather than long.

You can see on the picture below that there is a half-tray to the far right, not a big deal, once I saw the mistake, I fixed-up the design file and was able to move the animal pay trays that would have been junk to the space that would have been empty at the end of the laminated board at SandboxRanch.com.

The reason one tray is already cut-out is because I wanted to test my program first, as this was the first time I was cutting this with my Thermwood, I wanted to double check speeds, feeds and tool changing before doing a production run to find-out I overlooked something important.

With a machine like this, it’s very easy to produce scrap if you don’t have all your ducks in a row, I learned a lot during this production run by the way, so each successive video will just be an improvement of lessons to increase productivity.

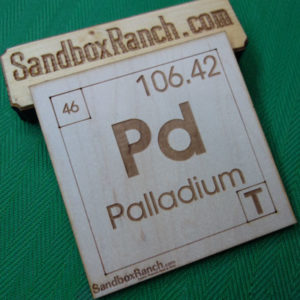

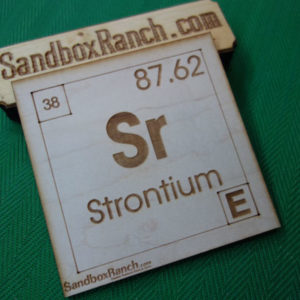

From cigar ash trays to pill trays, their production is all similar, just the design and materials are different.

Custom trays are something I’ve done a lot of at CNCROi.com but never to this level of upmost customization and quality right off the machine, having a tool changer is a game changer alone, a super rigid machine is yet another and all the experience from years of custom CNC woodworking are really paying dividends with this totally industrial CNC router.

What I especially like about what I’m producing with my Thermwood is the lack of sanding requirement, it’s a small thing, but having such a powerful machine with zero play gives a lot of benefits and that’s a major one.

The spindle is super-powerful, the bits are custom and wow does it show when this production run of custom animal paw trays that are now available for purchase at SandboxRanch.com.

Need custom trays of any size, shape or design? Contact SandboxRanch.com right now!